SCADA RTUs

The Remsdaq SCADA systems division designs and manufactures products for electricity substation control and automation in generation, transmission and distribution. Our advanced technologies are relied upon by several District Network Operators (DNOs) in the UK and overseas and place Remsdaq at the forefront of the energy revolution as a SCADA systems manufacturer in the UK.

SCADA Remote Terminal Units

A range of SCADA RTUs for small count applications to single pole-top and fully integrated substation control systems.

View products

SCADA Systems Software

A range of local user logic and configuration tools, web servers and operator interface SCADA software packages.

View products

Human Machine Interfaces (HMI)

Powerful, multi-function and industrialised touch screen HMIs for use in many applications and sectors.

View productsWhat are SCADA Systems?

SCADA stands for Supervisory Control and Data Acquisition and Remsdaq is one of the UK’s leading SCADA systems manufacturing companies. Remsdaq manufacturers a range of SCADA remote terminal units and supplies the RTUs with SCADA monitoring and control software as part of a SCADA system that is used for for substation control and automation.

SCADA Systems for Automated Substation Monitoring and Control

Remsdaq has been in the SCADA systems business sector for over 40 years and supplies several clients in the UK and overseas including:

- District Network Operators (DNOs)

- Utilities

- Global integrators

- Switchgear and automation manufacturers

- Systems integrators

Conformance to open industry standards, flexibility, scalability and reliability are cornerstones of the company’s ability to respond to utility transmission and distribution substation automation requirements alike. Callistonx and its supportive hardware and software library, together with Celestenx user interface facilities provide an overarching solution to meet even the most demanding substation applications.

Callistonx is not just an IEC 61850 compliant logical device; the extent of its configurable hardware, database and logical node software enables it to be tailored to meet a wide variety of applications that would commonly occupy multiple logical devices. The powerful, flexible building block properties of Callistonx and Celestenx seamlessly assemble for a total distributed substation automation solution that may encompass:

- Multiple fault tolerant Ethernet Station Bus arrangements, physically presented as 100 BaseFX or as 10/100 BaseT(X), plus optional 100 BaseFX Process Bus to handle raw sampled data.

- Callistonx Bay Controller with flexible physical I/O and configurable logical node functionality for virtualisation of diverse substation plant requirements. For more stringent system requirements the Callistonx bay controller can be deployed in a bumpless transfer hot standby configuration.

- Direct VT, protection CT and measurement CT interfaces to a single Callistonx fully integrates protection, protection related functions and automatic process control as well as highly accurate metering and measurement logical node groups in a single logical device.

- Multiple serial interfaces on each Callistonx physically presented as isolated RS 232, isolated RS 485 or fiber and with configurable interface protocols to support legacy IEDs and other serially connected devices.

- Extensive database capacity, flexible protocol library, integral GPS option and comprehensive communication interfaces, coupled with peer to peer station bus communication, ensures that a Callistonx processing node also efficiently satisfies any requirement for hierarchical gateway communication with a SCADA or dispatch control center. Fault tolerance is inherently provided by merely replicating the Callistonx gateway.

- Embedded pre-designed application library for commonly encountered automation applications such as synchro-check, auto-reclosing, OLTC and under-frequency load shedding are complimented with the IEC 61131-3 PILoTnx user programmable logic that executes peer-to-peer across the networked Callistonx processing nodes.

- Sequence of event recording to a system-wide accuracy of better than 1 millisecond across the entire station bus. GPS sources can be optionally provided as an internal build option to the Callistonx processing node or provided from an external device. Build options are available for multiple redundancy of the GPS source.

- Flexible database I/O and functionality configuration with CaSEnx which provides the necessary tools for construction of a single line diagram of the target substation, creation of an overall substation configuration description file for all Callistonx logical nodes via an extendable library of generic definitions and downloading configured XML files to the individual Callistonx nodes across the station bus.

- Individual bay level HMI via Touchnx to support local plant monitoring, operation and diagnostics via a highly configurable full colour graphics panel mounted touch screen terminal.

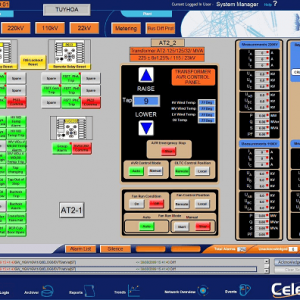

- Powerful Energy Edition Celestenx substation HMI configured in single computer? or fully redundant hot standby configuration. Celestenx provides all requisite operator interface requirements for safe and secure substation supervision and control, together with substation management tools for access and setting of protection devices, plant tagging, reports and archiving.

- Automatic upload of the XML database from Callistonx bay controllers to Celestenx thus facilitating single point system configuration from CaSEnx to simplify system design and safeguard against errors often encountered with multiple levels of system data entry.

- Password authenticated web browser access to individual Callistonx bay controllers or gateways locally via the station bus or remotely via an approved internet or intranet connection for extensive monitoring and diagnostic facilities, authorised control, parameter checking and setting and report acquisition via Viewnx.

Remsdaq is ready to respond to your substation automation requirements with a system engineered and configured from a standard library of field proven hardware and software modules.

SCADA System Applications

Increasing demands for more sophisticated Advanced Distribution Automation solutions to improve utility operational efficiency, quality of supply, reliability and security are an inevitable consequence of the industry progression towards Smart Grid networks.

With its unique capability to respond to a multiplicity of applications Callistonx provides an unmatched capacity to satisfy the operational and application demands, with satellite master station configurations integrated via the Celestenx HMI platform. Remsdaq Advanced Distribution Automation solutions are modularly configured to encompass any or all of the following facilities:

- Single node Callistonx processing node for virtually any type of distribution plant outside the substation (load break switch, sectionalising switch, capacitor bank, automatic voltage regulator). Dependent upon the application the Callistonx incorporates full supervisory control, feeder management protection and protection related functions, full metering and measurement data, power quality data plus fault detection and disturbance analysis records.

- Intelligent temperature compensated battery management with extensive diagnostics and auto test facilities to provide the best possible battery operational service.

- Single node Callistonx processing node for supervision, control and automation functions for up to 6 substation feeders, including feeder management protection and protection related functions, power system metering and measurements, power quality data, fault detection and disturbance analysis records.

- Networked system configurations to meet utility requirements, including fiber optics, BPL, WiMax, GPRS, spread spectrum radio, etc. Communications media offering peer-to-peer operation improves the overall system operation.

- Extensive protocol configuration options to meet hierarchical communication requirements and to also support legacy and serial IED interfaces that may require integrating into the overall system.

- Embedded pre-designed application library for commonly encountered automation applications such as auto-reclose, VOLT/VAR, Fault Passage Detection. Auto Sectionalising and Load Restoration are complimented with the IEC 61131-3 PILoTnx user programmable logic that executes peer-to-peer across suitably networked Callistonx processing nodes.

- Extended IEC 61850 logical node functions for control of embedded generation plant, synchro-check, Micro Grid islanding, etc.

- Real time synchronisation across the network or alternatively option of integrated GPS receiver directly on the CallistoNX processor module.

- Identical CaSEnx configuration facilities to those utilised for substation automation applications with full upload and download over the system network.

- Identical Viewnx password authenticated web browsing facilities as those provided for substation automation systems.

- Integration of Viewnx for local user compact interface or Celestenx for comprehensive micro Grid or remote control centre operation.

Remsdaq is ready to respond with an advanced Callistonx solution that fulfils your current distribution automation needs, and provides the requisite future-proofing against ongoing plant and operational developments. We are one of the leading SCADA systems manufacturers in the World with an innovative solution to supervisory control and data acquisition.

Electricity Utility Automation

Remsdaq has a well-established record in the supply of SCADA systems for use in substation automation applications. As a SCADA systems manufacturer the company has been developing and manufacturing products for over 35 years and works with many of the UK’s electricity suppliers and District Network Operators. With its strong reputation for innovation and engineering, the company is often involved in research projects and new technology designs for use on the grid.

The electricity grid itself is experiencing massive change due to a range of factors. Renewable power generation including solar PV and wind turbines has introduced multiple points of connection to the grid and introduced more complexity to the electricity supply model. Demand for electricity is also rising rapidly. The UK has a growing population that is itself becoming more reliant on electricity and electrical devices and goods. The electric vehicle (EV) revolution will place further demand on the electricity grid as the country moves towards that of a low carbon dependent one. The UK is also a principle hub in Europe for the datacentre industry whose energy consumption is well documented as high.

By continuing to use the site, you agree to the use of cookies. more information

The cookie settings on this website are set to "allow cookies" to give you the best browsing experience possible. If you continue to use this website without changing your cookie settings or you click "Accept" below then you are consenting to this.